Product Series

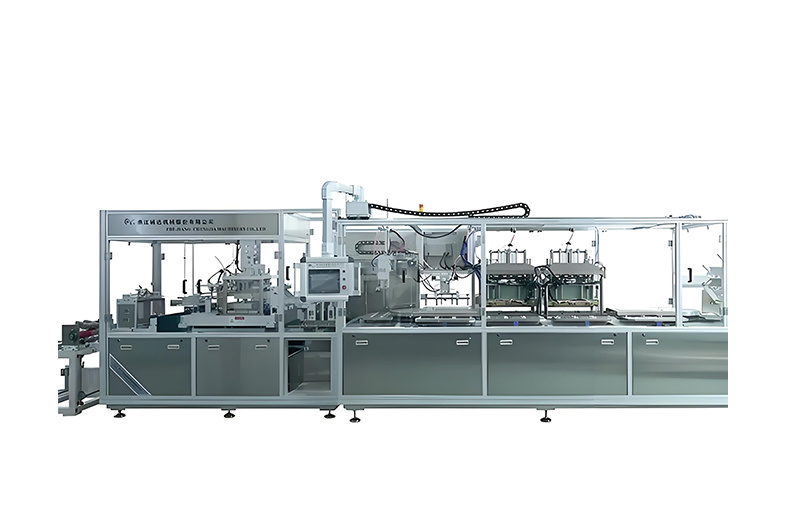

Automatic Paper Card Blister Packaging Machine

Classification:

keywords: Automatic Paper Card Blister Packaging Machine

E-mail:

Telephone:

Details

- Introduction

The DC-600 Automatic Paper Card Blister Packaging Machine is a precision-engineered solution designed for half-cover sealed blister packaging. Built to optimize workflows and preserve product integrity, it is ideally suited for medium to high-volume production environments across diverse industries, combining efficiency with adaptability to meet varied packaging needs.

- Applications

This versatile machine caters to a wide range of products across multiple sectors:

- Daily Commodities: Personal care items, household products, and daily consumables.

- Small Hardware: Batteries, electronic components, adhesives, and DIY tools.

- Stationery: Writing instruments, art supplies, correction products, and office essentials.

- Automotive Parts: Brake pads, spark plugs, sensors, and engine components.

- Cosmetics: Lipsticks, compact powders, beauty tools, and skincare samples.

- Toys & Novelties: Miniature vehicles, action figures, puzzles, and craft kits.

- Features

- Precision Forming: Equipped with customizable molds to create tailored blister designs, ensuring a perfect fit for diverse products.

- Efficient Sealing: Uniform heat distribution guarantees reliable half-cover seals, enhancing packaging integrity.

- Material Compatibility: Compatible with PVC, PET, and eco-friendly alternatives, supporting sustainable packaging choices.

- High-Speed Production: Servo-driven systems enable continuous, high-efficiency operation to meet large-volume demands.

- Modular Design: Easily integrates with feeding systems and secondary processes, offering flexibility in production lines.

- Technical parameter

Item | Parameter |

Stable production frequency (based on equipment display) | 8–15 (molds/min) |

Typeset size within the effective specification of cardboard | 600mm×200mm×200–700g/cm² (single-sided hot-melt adhesive coating) |

Single heat sealing: Clamping force (KN) | 20–55 (adjustable) |

Compressed air pressure (Mpa) (provided by the demander) | ≥0.55–0.8, oil-free, water-free, dry and clean air source |

Compressed air consumption (m³/min) | Approximately 0.5 |

Vacuum source (built-in to the equipment) | Extraction rate > 30 m³/h, vacuum degree p = -0.05 to -0.08 Mpa |

Power supply (three-phase five-wire) | 380V 50Hz 40A (the demander shall provide a 6mm² three-phase five-wire power cord and main power switch) |

Total power (KW) | Maximum 15KW (fluctuates slightly depending on configurations) |

Equipment installation environment | Relative humidity 45–65%, temperature < 30℃, non-clean area |

Overall dimensions (Length×Width×Height) | 4500×1250×2100 (mm) |

Net weight (Kg) | Approximately 2500 |

Related Products

Message

If you have any need, please feel free to contact us

Join Our Newsletter

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

We will provide you with the most professional advice