Product Series

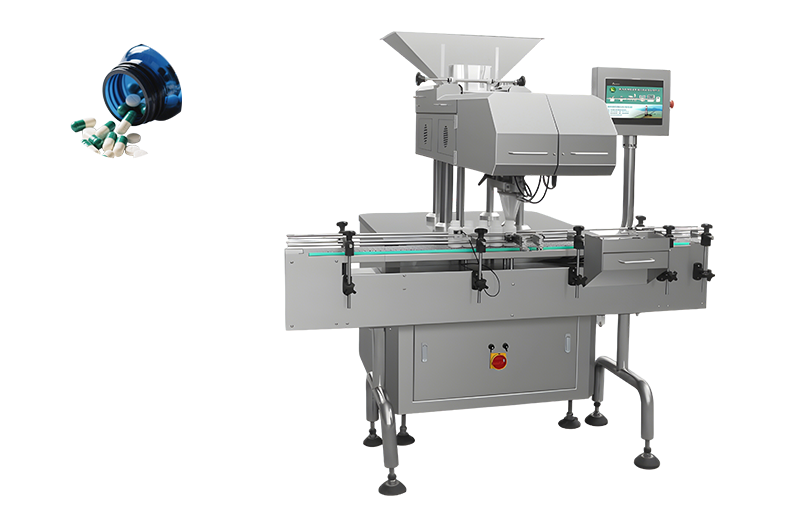

Automatic 8 channel counting machine

Classification:

keywords: Automatic 8 channel counting machine

E-mail:

Telephone:

Details

Working Principle

During operation, pour medicinal granules into the top hopper. Adjust primary, intermediate, and final vibrating feeders to make the piled granules turn into a continuous strip and slide down to the feeding port. Granules then fall into the detection channel one by one. Using the photoelectric effect, the signals generated when granules pass the infrared sensor are input into the FPGA high - speed microprocessor for counting. The device suits soft/hard/transparent capsules, tablets, pills, etc. The granule sliding track is stepped (2 - or 3 - layer), with granules moving layer - by - layer and a set distance between them to avoid overlapping.

Main Performance Features

1.The electronic granule counting machine combines photoelectric and microcomputer systems for accurate counting. It can count various products like tablets, capsules without changing mechanical parts. The feeding nozzle is customized. It has a high - speed microprocessor and a Chinese - display operating system for parameter setting. The sensor uses American chips, making the control system accurate and concise. The sensor and main control boxes are sealed and easy to replace (within 10 s by skilled workers).

2.The filling amount is adjustable with no error, ranging from 1 - 9999 granules per bottle. It has an automatic error - rejection system to ensure accurate counting, with an unqualified rate within 0.1‰ (usually 1 granule more in unqualified cases). It can remove fragments.

3.A double - axis cylinder controls bottle feeding, medicine filling, and bottle releasing, featuring a simple structure, convenient adjustment, and stable control.

4.Equipped with a photoelectric control device, the machine stops automatically when there's no bottle or bottle blockage and restarts when normal.

5.For different - height bottles, electric adjustment with upper and lower limit switches can be controlled on the touch screen.

6.In case of a failure, the machine stops and shows alarm information on the screen, and troubleshooting can be done according to the displayed operation method.

7.The modular design with cylinder - locked components enables tool - free disassembly, facilitating maintenance and avoiding risks of fasteners falling into the bin.

8.The granule counting head has an automatic cleaning function with an adjustable time according to dust level.

9.It uses a full - wave frequency - conversion and spring - combined vibration module, reducing noise by at least 10 dB compared to peers.

Dedicated Dust Removal Device (Optional)

1.Some tablet dust falls into the medicine trough through corrugated - plate gaps and is sucked away by the vacuum cleaner.

2.A fully - enclosed cover sucks dust into the vacuum cleaner, similar to a household range hood.

3.The electronic eye has an automatic cleaning function with an adjustable time interval on the touch screen.

4.These three dust - removal methods ensure almost zero dust in the bottles.

Main technical parameters

| Applicable bottle shape | round、square plastic bottle |

| Filling material | 00~5#capsule, soft capsule,Φ5.5~12compressed tablet, special-shaped tablet, sugarcoated tablet, Φ3~12 pill, gummy |

| Production capacity | 20~50 bottles per minute(It depends on the bottle size,filling quantityand pill size) |

| The setting range of bottling volume | 1-9999 |

| Power supply | AC220V 50Hz 1.2kw |

| Accuracy rate: | >99.5%(higher than the industrial standard ) |

| Air pressure(Mpa) | 0.6 |

| Overall dimension(mm) | 1600×1400×1560 |

| Weight(kg) | 350 |

Related Products

Message

If you have any need, please feel free to contact us

Join Our Newsletter

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

We will provide you with the most professional advice