Product Series

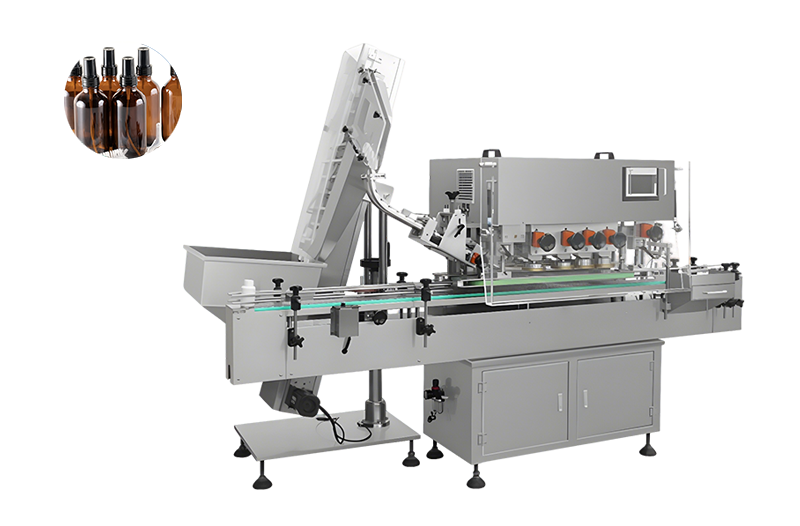

Capping Machine

Classification:

keywords: Capping Machine

E-mail:

Telephone:

Details

Working Principle

Once the bottle enters the capping process, the bottle - clamping mechanism adjusts according to the cap size and then clamps the bottle body. Caps are fed and reversed for adjustment. Next, the bottle moves to the capping station, where the capping wheel tightens the cap. An infrared photoelectric detector checks cap quality and the presence of aluminum foil inside. Defective products are removed, and qualified ones proceed to the next process.

Main Performance Features

1.Wide applicability. The standard equipment fits caps with a diameter of Φ15 - Φ65mm and a height of Φ8 - Φ30mm. Production capacity and cap - sorting speed are adjustable from 10 to 150 bottles per minute, with an operating rate over 99.9%.

2.Equipped with an independent elevator for automatic cap sorting. There's a photoelectric control device. When no caps are detected, the bottle - separating motor stops, and an error is shown on the screen.

3.Features an automatic reverse - cap dropping device to prevent reverse - capped bottles from entering the next process.

4.No need to change molds. Just a slight adjustment is required. Adjust the distance of capping wheels, each with a digital display for easy and clear operation.

5.The rotation speed of capping wheels, and the speeds of the bottle - clamping conveyor and transport chain can be adjusted by frequency conversion. Parts of the equipment in contact with medicine are made of 304 stainless steel, meeting GMP requirements.

6.Opposed photoelectric sensors are used to automatically detect and remove unqualified products such as tilted caps, cap - less bottles, and loose - capped bottles.

7.Opposed photoelectric sensors are also used to detect and remove products without aluminum foil. With a large adjustment range, it can be adjusted freely within the capping machine's adjustable range according to cap size, bottle diameter, and bottle height, without changing molds or capping heads.

8.Equipped with a photoelectric control device. When the tablet - counting machine stops, cap feeding stops automatically. When there are no caps, cap feeding starts automatically. The capping wheels are made of a new high - tech, wear - resistant material that doesn't damage caps, greatly extending their service life.

Main Technical Parameters

| Maximum Production Capacity | 150 bottles/minute |

| Bottle Specification(ml) | 15 - 300 |

| Cap Diameter(mm) | 15 - 65 |

| Bottle Body Diameter(mm) | 20 - 100 |

| Bottle Height(mm) | 45 - 220 |

| Voltage/Frequency | AC220V/50Hz |

| Power(Kw) | 1.5 |

| Overall Dimensions (L x W x H)(mm) | 2600x1200x1840 |

| Weight(Kg) | 613 |

Related Products

Message

If you have any need, please feel free to contact us

Join Our Newsletter

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

We will provide you with the most professional advice