Product Series

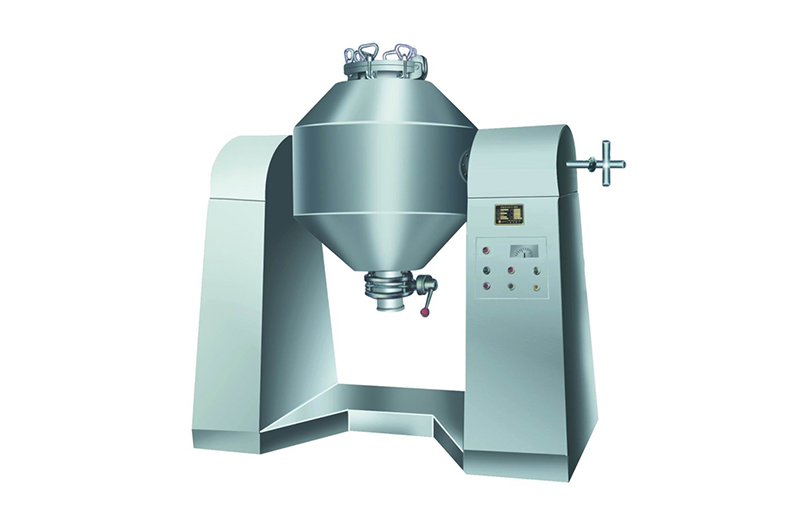

Double-cone rotary dynamic vacuum dryer

Classification:

keywords: Double-cone rotary dynamic vacuum dryer

E-mail:

Telephone:

Details

Double-cone Rotary Dynamic Vacuum Dryer

SZG-300

Applications:

The double-cone rotary vacuum dryer is widely used for drying powdered, granular (including crystalline) materials in industries such as pharmaceuticals, chemicals, food, dyes, and powder metallurgy.

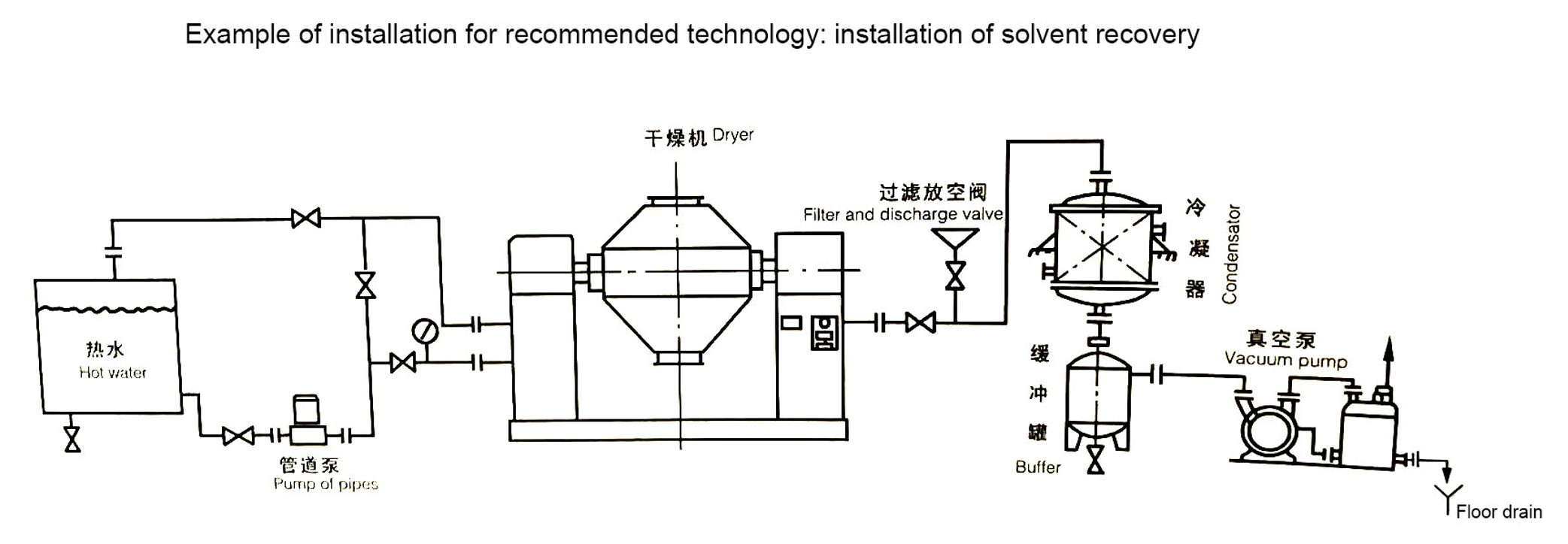

The dryer features a cylindrical middle section with conical ends. The top of each cone is equipped with an inlet and outlet, which also serves as a manhole. The container has three layers (inner, middle, and outer). The middle jacket uses steam (with a pressure of ≤0.6MPa gauge pressure), circulating hot water, or heat-conducting oil as the heating medium. The outer insulation layer is made of ultra-fine glass wool, providing excellent thermal insulation. Materials are placed in the inner container; during the rotation, the materials tumble and absorb heat through the container wall, undergoing rotary drying under vacuum conditions. This accelerates the drying speed, prevents the surface of the materials from yellowing during drying, and significantly shortens the drying time—only about two-thirds of the time required for drying similar materials in a vacuum oven—thereby improving labor productivity. It is particularly suitable for drying materials that are at risk of oxidation and heat-sensitive materials. Moreover, it shows greater advantages when drying materials that need to maintain their crystalline structure, materials with strictly restricted metal ions, and materials where volatile substances (or toxic substances) need to be recovered

This dryer is easy to operate, with convenient feeding and discharging, which greatly reduces the labor intensity of workers. At the same time, it reduces environmental pollution to materials during the drying process, improves product quality, and meets the requirements of the "GMP" pharmaceutical management standards.

Technical parameter:

Item | Parameter |

Volume of cylinder | 300 Liter |

Effective working volume | About 150 Liter |

Rotational speed | 0-10 rpm |

Power of dryer | 2.2 kw |

Pressure inside the drying rack cylinder | 0.096MPa |

Vacuum degree inside the cylinder | -0.098MPa |

Heat transfer oil heater | 0.5 m³ |

Supporting Components

- One control box for the main machine (installed inside the main machine) with panel-type operation; equipped with start,stop, and jog buttons, and the main machine speed is adjusted by frequency conversion

2. One set of heat-conducting oil heating system:

a) Heat-conducting oil volume: 0.5 m³; the inner wall of the heat-conducting oil tank is made of carbon steel with a thickness of 4mm; the outer wall is made of 1.5mm carbon steel plate; the shell is insulated with aluminum silicate as the insulation material, with an insulation layer thickness of 80mm. The external dimensions of the hot water tank: 800mm (length) × 800mm (width) × 800mm (height).

b) The heat-conducting tank is heated by electric heating; electric heating power: 32kw; the electric heating tube is made of stainless steel; the hot water temperature is automatically controlled at a constant level.

c) One heat-conducting oil pump; model: 1.5KW.

d) One set of oil inlet and outlet pipelines for the heat-conducting oil system, made of carbon steel; equipped with globe valves, liquid level gauges, blowdown valves, etc.

3. One set of vacuum system:

a) One vacuum pump: model 2SK-1.5A, 4.0KW.

b) One buffer tank: made of 304 stainless steel, volume: 100 liters; equipped with 2 globe valves.

c) One set of vacuum system pipelines (made of 304 stainless steel), 1 globe valve, and 1 check valve.

4.Electrical control system:

a) Switch control and indication for the vacuum pump, heat-conducting oil pump, etc.

b) Switch and indicator light for the heat-conducting oil heating system, with automatic temperature control and adjustment for the heat-conducting oil, as well as digital display.

c) Explosion-proof button control, with a power supply of 220V/380V, three-phase, 50Hz.

Related Products

Message

If you have any need, please feel free to contact us

Join Our Newsletter

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

We will provide you with the most professional advice