Product Series

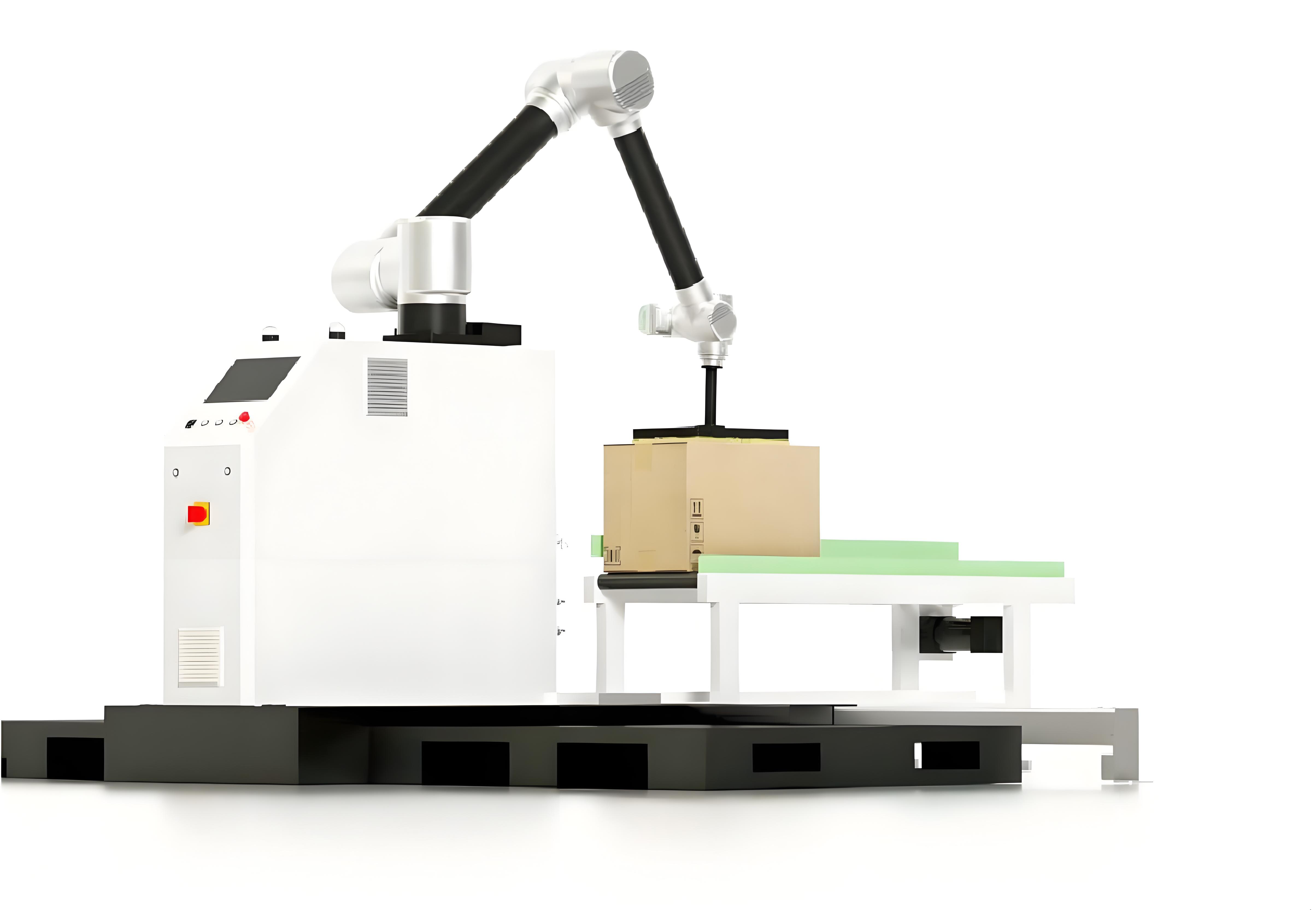

Full-automatic Palletizing Machine

Classification:

keywords: Full-automatic Palletizing Machine

E-mail:

Telephone:

Details

It only takes 5 minutes to realize unmanned handling.

Preparation - Palletizing mode setting - Palletizing A - Palletizing B – Completion

Product Introduction

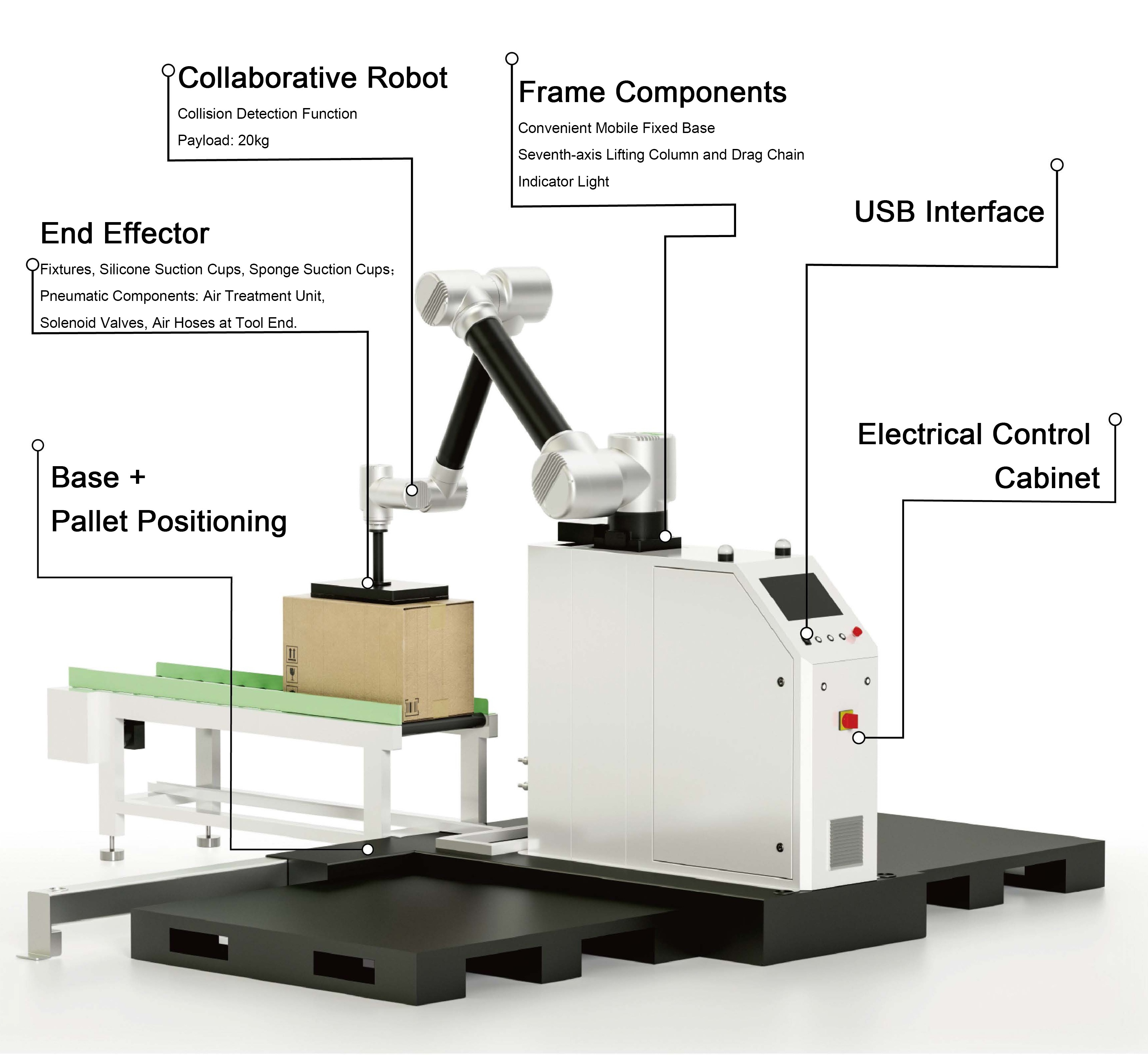

The Collaborative Palletizing Machine Workstation is a tailor-made handling expert for multiple industries, including food, pharmaceuticals, 3C, printing, and daily chemicals. With visual programming design, it only takes 5 minutes to input information, enabling the stacking of products/cartons onto pallets for unmanned handling. The user-friendly visual programming allows operators to easily control the robot; the high-load designed end-effector can grasp products weighing up to 20KG. This machine features flexible deployment, small footprint, simple wiring, convenient maintenance, and high efficiency, capable of palletizing 6-10 cartons per minute.

Product Characteristics

- Simple Operation: Adopts touchscreen design. Just manually input and save parameters to achieve unmanned handling.

- Easy Operation Process: Preparation - Palletizing mode setting - Palletizing A - Palletizing B - Completion.

- Dual-sided Palletizing: Capable of palletizing on both left and right sides.

- Labor Saving: Machine replaces manual labor in goods palletizing operations.

- Easy Maintenance: With precision components, only the suction cup needs to be replaced after 300,000 uses.

- High Safety Factor: No need for fence safety isolation, ensuring high reliability and safety.

- Flexible Expansion: Can be matched with production lines such as carton opening machines and carton labeling machines to provide customers with overall goods packaging solutions.

PARAMETERS

|

Speed |

6-10 box /min |

|

Effective Bearing Capacity |

20KG |

|

Working Area |

3590mm*1724mm |

|

Voltage/power |

220V, 3kw |

|

Working Radius |

1600mm |

|

Application Carton Range |

Length: 200-500mm, Width: 200-500mm, Height: 200-400mm (based on 1200mm×1200mm pallets) |

|

Palletizing Height |

Fixed base: 1650mm; Customizable upgraded base: 3000mm |

|

Pallet Specifications |

Maximum size: 1200mm×1200mm; Materials: Plywood, Plastic, Wood |

|

Stacking Pattern |

AB palletizing (interlocking layer stacking) |

|

Air Pressure & Consumption |

Pressure: 0.5-0.8 MPa; Air consumption: 350-450 NL/min |

|

Repeat Positioning Accuracy |

±0.04 |

Machine Details

Operating System

Teach Pendant and Cable

12.1-inch High-sensitivity Capacitive Touchscreen / 7-inch All-in-One Computer

WSC Collaborative Palletizing Robot System V1.0

Related Products

Message

If you have any need, please feel free to contact us

Join Our Newsletter

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

We will provide you with the most professional advice