Product Series

Semi-Automatic Gummy Machine

Classification:

keywords: Semi-Automatic Gummy Machine

E-mail:

Telephone:

Details

Semi-automatic gummy machines can make different kinds of gummies, such as single-color, double-color, and center-filling gummies. Automated gummy machines have a total capacity of 6,000-10,000 gummies per hour. It can reduce labor costs, save space, and enable flexible production quantities. It has easy cleaning and changeover design that allows your product to focus on quality and control.

Operated by PLC, our system ensures precise filling forms, offering high accuracy, simple operation, and low failure for quality control.

Specifications

| Candy weight(g) | 1-10 |

| Capacity(kg/h) | 30-40 |

| Output(pcs/h) | 10000 |

| Depositing Speed(n/min) | 15-30 |

| Electric power needed(mm) | 670*670*520 |

| Total length(mm) | 670*670*520 |

| Weight of Machine(kg) | 200 |

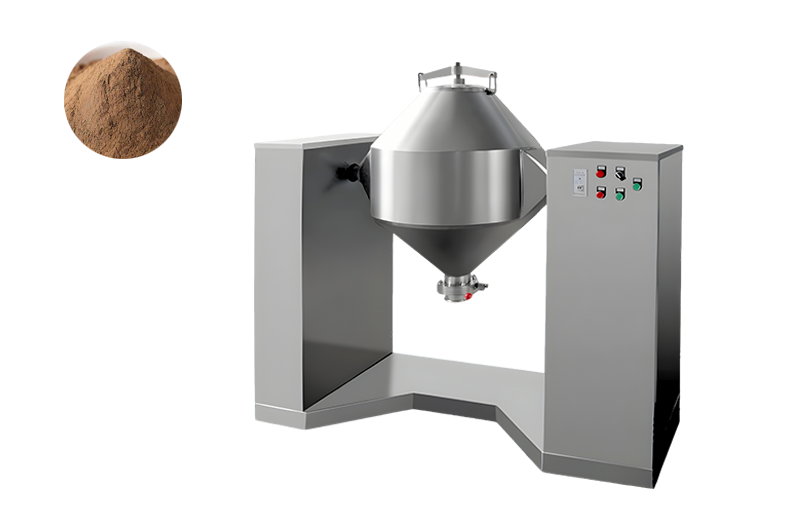

Cooking System

This is a title cooker for dissolving and mixing ingredients. After the sugar, glucose, and any other raw materials needed are mixed into syrup, and then title the cooker and make the syrup come out.

Depositing & Cooling Unit

A depositor comprises a depositing head, mold circuit, and cooling tunnel. The cooked syrup is held in a heated hopper fitted with many individual ‘pump cylinders’ – one for each deposit.

The upward piston motion draws candy into the pump cylinder and pushes through a ball valve on the downward stroke. The mold circuit moves continuously, and the whole depositing head reciprocates back and forth to track its movement.

All the movements in the head are servo–driven for accuracy and linked mechanically for consistency. A two-pass cooling tunnel is located after the depositor with ejection under the depositor’s head.

For hard candy, ambient air is drawn from the factory and circulated through the tunnel by a series of fans. Jellies normally require some refrigerated cooling. In both cases, when the candies emerge from the cooling tunnel, they are at final solids.

Mold with QuickRelease Tool

Molds can be metal with a non-stick coating or silicone rubber with either mechanical or air ejection. They are arranged in sections that can be easily removed for changing products and cleaning coating.

Related Products

Message

If you have any need, please feel free to contact us

Join Our Newsletter

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

We will provide you with the most professional advice