Product Series

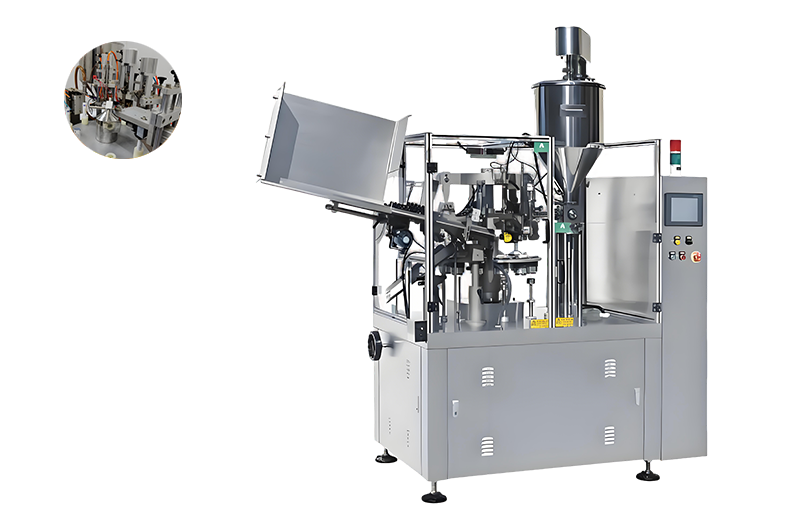

aluminum tube filling and sealing machine

Classification:

keywords: aluminum tube filling and sealing machine

E-mail:

Telephone:

Details

Chapter I Company Introduction

Our company is one of the fastest growing packaging machinery company in China, that has constantly followed a path created by its own will, hard work and determination. The One Packaging is involved in research, manufacturing and marketing of packaging machines.

We are specialized in packing and packaging machines including mixer, vacuum homogenizer, pump, bag packaging machine, bottling machine, filling machine, rinsing machine, capping machine, aluminium foil sealing machine, labeling machine, unscrambler, turntable, tube filling and sealing machine, counting machine, cartoning machine, monoblock filler stopper capper, production lines, and non-standard packing machine for cosmetics, pharmaceutical, chemical, hygienical, food, beverage industries.

our vision is to build the leading name of international partners. Today, The One packaging machines have been installed in various countries in the world and are well appraised by our overseas customers. We have achieved the very important first step towards our vision.

We approach not only to supply the high-quality packaging machines, but also to provide high-quality service. Today's growth of the company is a result of regular technologies improvement and observance of the quality concept. We will try our best to meet all requirements of clients about packaging machines.

Chapter II Summary

Thank your for your using the automatic tube filling & sealing machine produced by our company.

With the design, manufacturing, assembly, debugging, as well as main parts and materials being fully in accordance with GMP requirements, the automatic tube filling & sealing machine produced by our company has such features as smooth and flat surface, free of dead corner, being innoxious and non-smell, free of pollution, easy cleaning, and easy maintenance and servicing.

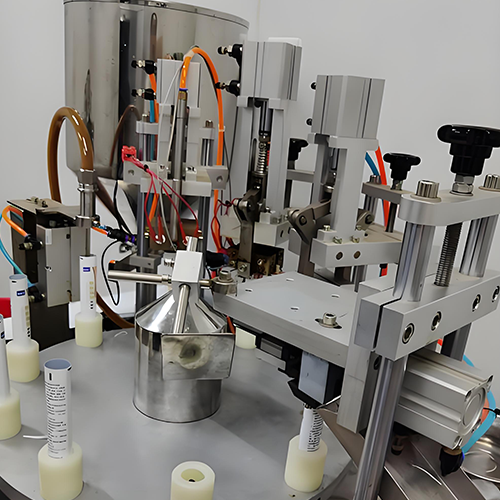

Thanks to the compact structure, simple and convenient operation, the machine is applicable to the demands of users from the industries such as medicine, food and daily chemical industry etc. The machine can smoothly and accurately fill various paste, ointment and viscous fluids etc. materials into the tube. Hot air heating will be carried out inside the tube through the heating head (made in Switzerland) and the operations such as sealing and batch No. printing etc. can be finished for plastic tubes and composite tubes. The highest production capacity of the machine can reach 2400 pieces/hour with an error of filling volume not more than 1%. The equipment is a kind of filling & sealing machine used to carry out internal hot air heating for plastic tubes and composite tubes through the operations of touch screen.

Chapter III Working Principle

Put in order the tubes to be filled on the tube bucket. After the tubes are arranged, through the automatic tube feeding device, they will be automatically inserted into the cup seats. The cup seats will rotate with the rotary table so that they will be positioned at different work stations. Put the ointments for filling into the lockable cone hopper. Through the plunger type quantitative filling valve directly connecting with the hopper, they will be accurately and automatically filled into the tubes staying at intervals on the work stations of filling. The large plate will continue its rotation and rapidly bring the tubes that have been filled with ointments to different work stations of sealing. The clamp mechanical hand will instantly seal the tube tail. Different filling volumes can be achieved through adjusting the filling volume adjusting dial. The hot sealing operation of full-plastic tubes and composite tubes of different tube diameters can be finished through changing different molds. After the sealing is finished, the mechanical hand for code printing will automatically print the words such as date of manufacturing and production batch No. onto the tube tail. Through the automatic tube discharging structure, the finished tube will be automatically sent into the tube collecting vessel.

Chapter IV Technical Parameters

| Model/name | NF-60 | Automatic Tube Filling & Sealing Machine | |

| Rated voltage | 380/220V (optional) | Rated current | 20A |

| Maximum speed | 50 tubes/min | Production speed | 1800-2400 tubes/hour |

| Tube diameter | Φ13- 50mm | Tube length | 210mm (max. length) |

| Hopper volume | 50 L | Heating temperature | 450℃ (max.) |

| Working air pressure | 0.5-0.7Mpa | Water consumption | Max. 2 L/min at 2 bar |

| Filling range | 5-250ml/tube | Filling accuracy | ≤±1% |

| Air pressure | 0.5-0.7MPa | Main motor power | 1.1KW |

| Outline dimensions | 1900×850×1900mm | Gross weight | About 850kg |

Related Products

Message

If you have any need, please feel free to contact us